Compliance Verification Measurements for ESD Worksurfaces

Here is a some guidelines on how to be in compliance for verification measurements for ESD Works surfaces.

Compliance verification measurements are periodic measurements that are taken to ensure that the ESD control items used as part of an ESD control program still meet the established limits.

Users will often ask the question “How frequently should we be measuring our ESD control items.“ 2020 does not specify how often measurements need to be taken. The required frequency is based your process, the value of the product that you are trying to protect, the importance of the ESD control item and the likelihood that the control item will fail.

Most companies will test work surfaces either monthly or quarterly. It is typically recommended that newly established programs test more frequently and then, as they gather data about the reliability of the ESD control elements extend the measurement frequency.

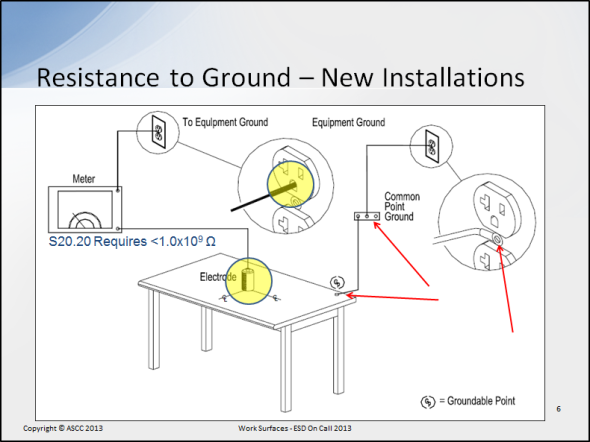

**ANSI/ESD S20.20 defines the compliance verification limits for work surfaces. The resistance to ground limit for a work surface must be less than 1.0×109 ohms. The compliance verification measurements for work surfaces are made following a procedure that is documented in the ESD Association’s Technical Report 53 or TR53.

**TR53 requires a single resistance to ground measurement using an open circuit resistance meter. The meter should have the capability to make resistance measurements using either 10 or 100 volts. 10 volts for measurements less than 1.0×106 ohms and 100 volts for measurements of 1.0×106 and above.

Before proceeding to make audit measurements it is a good practice to verify that your measurement equipment is functioning properly. Some considerations are:

- If your resistance meter is battery powered ensure that the batteries are good.

- Check the meter’s resistance leads for damage.

- Perform a system resistance test.

- Place a metal plate on top of an insulator

- Place a 5 pound electrode onto the plate.

- Clip one resistance meter lead to the plate and the other lead to the electrode.

Make a resistance measurement. The resistance should be less than 500 ohms.

One key component of a compliance verification measurement is that you are testing the ESD control item as it is found in the process. As an example, should a work surface be cleaned prior to making a compliance verification measurement? The answer is no. The process owner wants to know if the cleanliness of the work surface has a negative effect on performance of the work surface.

**ANSI/ESD S20.20 establishes the limit for work surfaces. They must have a resistance to ground of less than 1.0×109 ohms. The measurement location that is recommended is either the center of the work surface or the portion of the work surface that displays the most wear.

The image above shows the set-up for making a resistance to ground measurement. First you will notice how the work surface is grounded. **A ground wire runs from the work surface groundable point to the COMMON point ground. **A second wire runs from the common point ground to, in this case, the green wire electrical ground.

In order to make the resistance measurements the voltage lead is attached to the electrode AND the sensing lead is connected to the ground reference. For ANSI/ESD S20.20 compliant programs the resistance to ground must be less than 1.0×109 Ohms.

Recent Comments