Is ESD Walking Test mandatory to have for an EPA?

Recently, a customer asked a question regarding use of the ANSI/ESD STM97.2 Walking Test (Floor Materials and Footwear – Voltage Measurement in Combination with a Person). She wanted to know if it was necessary to have for an EPA (ESD Protected Area). In my opinion the STM97.2 walking test should be used as necessary as follows.

Applications for ANSI/ESD STM97.2 Walking Test

- Initially to “Qualify a floor” using selected footwear as required by S20.20. It has been reported that the new S20.20-2014 will require the 2007 version’s Method 2 for the Qualification for flooring and that Method 1 will be eliminated.

- Method 2 Requires STM97.1 Floor Materials and Footwear – Resistance Measurement in Combination with a Person a total Body System resistance measurement to ground shall be less than 1.0×109 ohms, and that Body Voltage measured per STM97.2 be less than 100 volts

- Method 1, which will be discontinued, required that total body resistance to ground as measured per STM 97.1 shall be less than 3.5×107 ohms and no body voltage measurements were required.

- Note that STM97.1 body resistance measurement should be performed at the same time as STM97.2 walking voltage is conducted for future reference.

- Method STM97.2 is also used to match new footwear to a floor to determine which shoe provides optimal performance; every shoe does not perform the same on different floor surfaces.

- Conduct STM97.2 when season or weather conditions change to obtain a performance picture of the floor/footwear combination over the characteristic annual conditions of the facility’s location.

- Use STM97.2 whenever troubleshooting ESD problems and assessing flooring maintenance

- STM97.2 is very important when performing process capability analysis to determine the lowest damage threshold ESDS device that can be safely handled in that particular process. When used in process analysis applications STM97.2 is used to assess risk of exceeding specific device HBM voltage thresholds, and to evaluate amount of charge transferred to production and other handling aids.

The following is some additional information that our colleagues may find helpful.

Having developed the original walking test step and measurement method that STM97.2 is based upon in the 1980’s, and presenting it to industry via the ESD Symposium in 1990, I find discussion of STM97.2 in today’s market quite interesting. Over the years we have found ways to enhance the accuracy of the measurement setup to reduce variables due to cabling selection and use. Also, when the SH&A test method was adapted to STM 97.2 by the working group they elected to ignore the Data Analysis portion of the paper. As many changes in device sensitivity, problem and process analysis have evolved, the time has come to focus once again on these two areas.

CABLE & INSTRUMENT SETUP

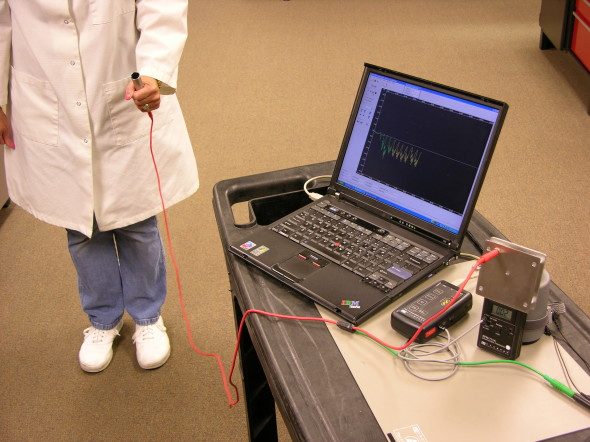

Numaguchi San, formerly of 3M Japan, is quite right in his recent Linked In comment regarding the effect of the measurement cable and Q=CV. In recording the data one must stabilize the connection between the body and the charge plate monitor (CPM). A shielded cable – grounded at one end — of defined length must be used. The result is a rather uniform connection where variables related to capacitance and inductance are reduced. This helps to reduce the effect on the recorded data caused by the cable’s movement and its relationship to ground. It also reduces the effect of external charges and resulting fields from the outer surface of the cable’s insulation. Does this totally eliminate all external effects caused by environment and movement? No, but it does reduce their impact considerably and provides a connection having rather constant capacitance characteristics.

Note that a ground connection separate from the CPM plate ground is required for the cable shield to prevent changing the CPM’s capacitance. (Capacitance in parallel is additive, such as resistance in series, which would increase system C and reduce the recorded V.)

To summarize cable and instrument setup, if the technique of defined length, grounded shielded cable is not used for the body voltage measurements, the results are only relative to the person making the measurement, the ambient conditions, instrument set up employed, and are typically not reproducible.

DATA ANALYSIS & VOLTAGE PROJECTIONS

Walking and resulting body voltage create a dynamic ESD system based on several factors. Body capacitance of the operator provides a minimum of 30% of the system capacitance. Thus, a small person having small feet and thick soles will typically generate higher body voltages than a large person with big feet – such as mine – on the same floor while wearing the same model shoe. Consequently, using average or peak voltage to qualify the performance of an expensive flooring/footwear combination is not prudent. Why? Because everybody has a different body capacitance and walks their own way. Yes, once again Q=CV and Q/C = V. There are two solutions to this problem, both presented in the original paper and employed in Prostat’s PGA-710B AutoAnalysis System® reporting function, which was designed for measuring and analyzing this dynamic system.

I should mention that accuracy is a function of the user, not only the instruments used for the measurement, or the necessary calculations for reporting purposes. All must be addressed as a measurement system. STM97.2 currently does not effectively address these variables.

If you observe the original 6-step walking pattern in STM97.2 there is a beginning and an end to the step. At the end point, one must pause for two reasons: (1) provide a separation between recorded steps; and (2) provide a minimum data point. While performing the 6-Step we simulate (a) body voltage generation during transport of products. When we pause with both feet on the floor body capacitance increases and voltage goes to minimum (Q/C=V), which simulates (b) body voltages at work stations and equipment while handling our most sensitive ESDS devices. In my opinion both the Walking and Standing voltages must be assessed to obtain a clear view of the footwear/flooring performance in a given operation. Of course, temperature and Rh can have significant impact on the test results and must be recorded.

One approach to using the data results of the walking test is a basic calculation using the average of maximum (Walking) and minimum (Standing) voltages and their respective standard deviations, i.e., 3x Standard Deviation added to, and subtracted from the average. Here, we define the probable range of body voltage generation using that footwear/flooring combination under the ambient (temperature and Rh) test conditions. This is what one would expect in a general population under these same conditions.

The other approach is a distribution analysis that calculates the probability of equaling or exceeding a given voltage – such as the HBM damage threshold of your most sensitive device under two different conditions, i.e., Walking and Standing. These approaches reduce dependence on one person’s specific body capacitance by using fundamental statistical calculations as simply implemented above. Several measurements using other people will confirm the approximate probable range and probability of equaling or exceeding a given voltage, and will further refine your overall measurements and assessment of the footwear/flooring combination.

The consequences of poor setup, verification of the measurement system and assessment of your data poses the risk of accepting bad materials, or rejecting good materials.

Recent Comments