Compliance Verification Training for Resistance to Ground

ANSI/ESD S20.20 requires that the ESD controls used in a compliant program be periodically verified;

- Frequency of verification is determined by the user

- The technical limits for most items are defined in the various tables of the standard

The ESDA Technical Report-ESD TR53-01-06 Compliance Verification of ESD Protective Equipment and Materials describes each of the required compliance verification methods which can be reduced to (6) basic procedures. This article described the procedure for Resistance to Ground.Equipment needed:

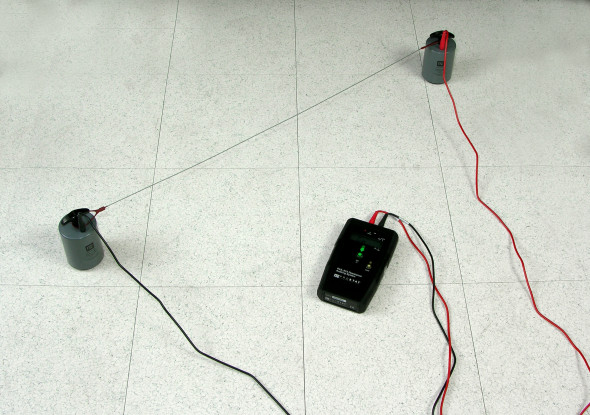

Resistance meter, such as the Prostat PRS-801, PRS-812 or PAS-853:

Test voltages:

- 10 volts for readings < 1.0×106ohms

- 100 volts for readings ≥ 1.0×106ohms

Upper resistance range:

- At least 1.0×1010ohms

Electrode, such as the Prostat PRS-801-W 5lb Conductive Rubber Electrode:

Total mass – 5 pounds ± 2 ounces

2.5 inch diameter conductive contact surface

Basic Procedure:

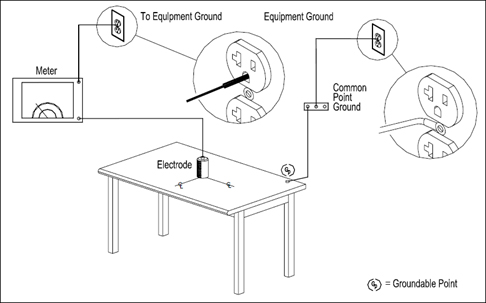

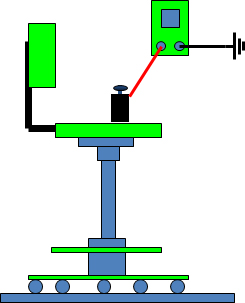

- Attach lead #1 to the high resistance meter and the other end to the measuring electrode.

- Attach lead #2 to the high resistance meter and the other end to ground.

- Place the electrode onto the surface to be measured and start the measurement process at a test voltage of 10 volts.

- If the reading is < 1.0×106 ohms accept the reading.

- If the reading is ≥ 1.0×106 ohms switch to 100 volts and repeat the measurement.

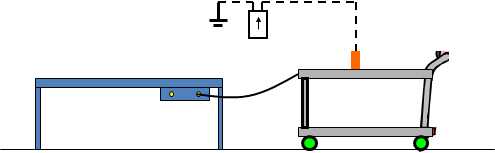

Cart grounded by a wire. Resistance measurement started after ground connection is made. Each shelf to be tested

Note 1 – “test as found” – The surface being measured should not be cleaned

Note 2 –If the user knows, through experience, that the item being measured has a resistance greater than or equal to 1.0×106 ohms it is not necessary to make the 10 volt measurement.

Ron Gibson is an SH&A Senior Associate specializing in manufacturing process control, training and facility certification in accordance with ANSI/ESD S20.20. He is well known internationally as an outstanding ESD practitioner and as a major contributor to ESD technology for the past 25 years. Visit his website at: http://www.staticcontrolconsulting.com/

Recent Comments